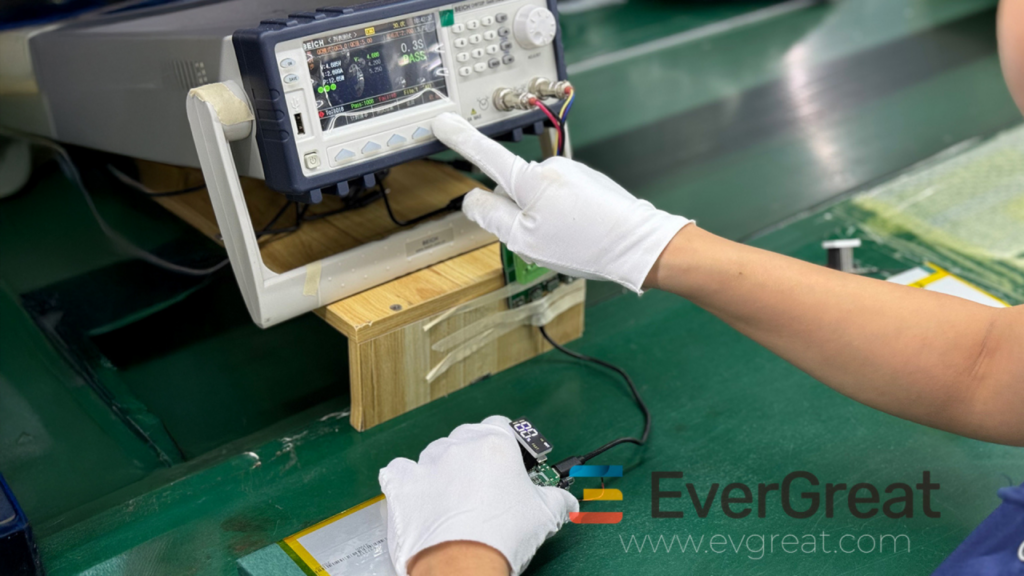

🖌️ Today I would like to share with you the importance of pre-production sample testing:

❗ Pre-production sample testing: a key step in quality assurance! The video shows our pre-production sample testing process, which is a key step in our strict quality control.

🔌 Verify product functionality and stability.

The primary goal of pre-production sample testing is to ensure that all functions of the product can operate normally. This stage of testing covers multiple aspects from charging performance, service life to safety protection functions, ensuring that every technical indicator meets the standard. Through strict functional testing, we ensure that the product can be used reliably in the hands of customers and avoid quality problems later.

🛠️ Discover and solve potential problems in advance.

Through comprehensive testing of pre-production samples, we can find any problems that may affect product performance in advance before mass production. This not only reduces the risk of errors in production, but also significantly reduces rework costs and ensures that each product can maintain consistent high quality standards during mass production.

💯 Ensure accurate implementation of customer customization requirements.

We understand that the needs of each customer are different, and pre-production sample testing is a key link to ensure that all customization requirements are accurately implemented. Whether it is design, material selection or LOGO printing, the purpose of testing is to ensure that every detail is exactly in line with customer requirements.

🛠️ Improve product reliability and reduce after-sales problems.

We are well aware that quality is not only the performance at the time of delivery, but also the reliability of the product in the long-term use in the market. Through rigorous testing of pre-production samples, we ensure that the product can stand the test of time, reduce after-sales problems, and provide customers with a worry-free use experience.

🤝 Lay the foundation for mass production.

Pre-production sample testing is equivalent to a “rehearsal” for mass production. Through testing, we confirm that each step of the production process is seamlessly connected to ensure that subsequent mass production can proceed smoothly. This step is an important basis for ensuring efficient production and avoiding delays.