📚 When you talk to suppliers about product logo and specifications printing, what information should you ask to ensure the quality is OK and make the supplier feel that you are very professional?

🌟 Tips for selecting Silk-Screen Printed: 🌟

📌 Material Compatibility

Silk-screen printing works best on flat, smooth surfaces like plastic, metal, glass, and fabric. Not all materials accept ink equally.

Tip: Confirm with your supplier whether your product’s material is suitable for silk-screen printing.

Example: For power banks, a smooth metal or ABS plastic surface yields sharp and vibrant prints.

📌 Design Complexity and Color Limits

Silk-screen printing is ideal for bold, simple designs with limited colors. Complex gradients or multi-color logos may require additional layers, increasing costs and time.

Tip: Simplify your logo for silk-screening, or consider digital printing if you need detailed artwork.

📌 Ink Types and Durability

Different inks are used for silk-screen printing based on the product’s material and use case. UV-resistant or waterproof inks might be necessary for outdoor or high-use products.

Tip: Ask your supplier about specialty inks if your product will face wear and tear.

📌 Surface Preparation and Adhesion

Proper surface cleaning and preparation are critical for good ink adhesion. Oils, dust, or uneven surfaces can affect print quality.

Tip: Ensure the manufacturer follows pre-print cleaning procedures for the best results.

📌 Print Size and Positioning

Accurate alignment and consistent positioning of your logo are essential for professional results.

Tip: Clearly specify the exact location and dimensions of your design. Provide mock-ups if possible.

📌 Minimum Order Quantities (MOQs) and Costs

Silk-screen printing often has higher MOQs due to setup costs for screens and inks.

Tip: If you need small batches, ask about digital printing options as a cost-effective alternative.

📌 Longevity and Maintenance

Silk-screen prints are durable but can wear over time, especially with frequent handling or exposure to harsh conditions.

Tip: For products like power banks or chargers, choose high-durability inks and protective coatings.

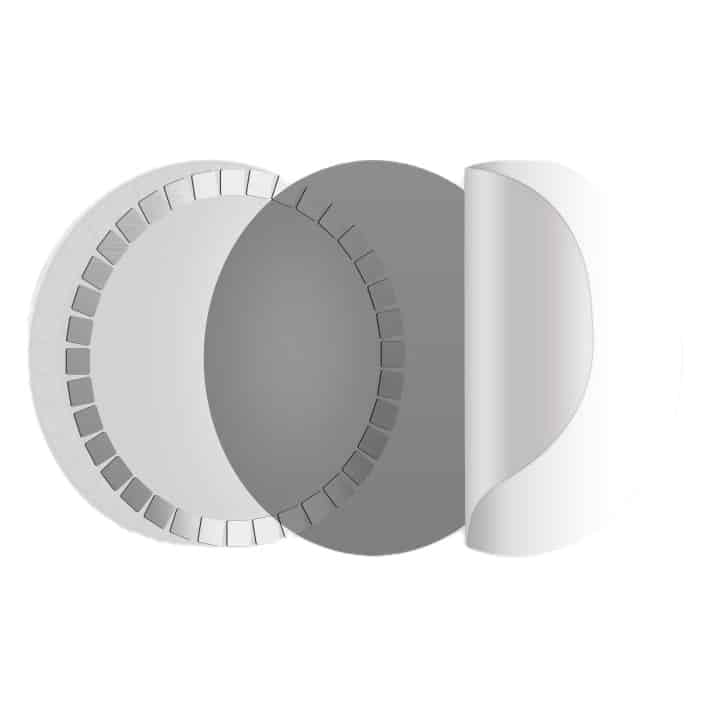

📌 The technique I am demonstrating in the video is pad printing, which is a type of silk screen printing. It is mainly used for printing irregular shaped items such as electronics, toys and promotional products.

💪 By understanding these factors, you can confidently navigate the silk-screen printing process and ensure high-quality results for your products. Always communicate closely with your supplier to clarify details and expectations!