How to Manufacture a Power Bank?

Making a power bank looks easy, but quality issues can ruin your brand. We’ll show you what truly matters in manufacturing for safety and performance, based on our years of experience.

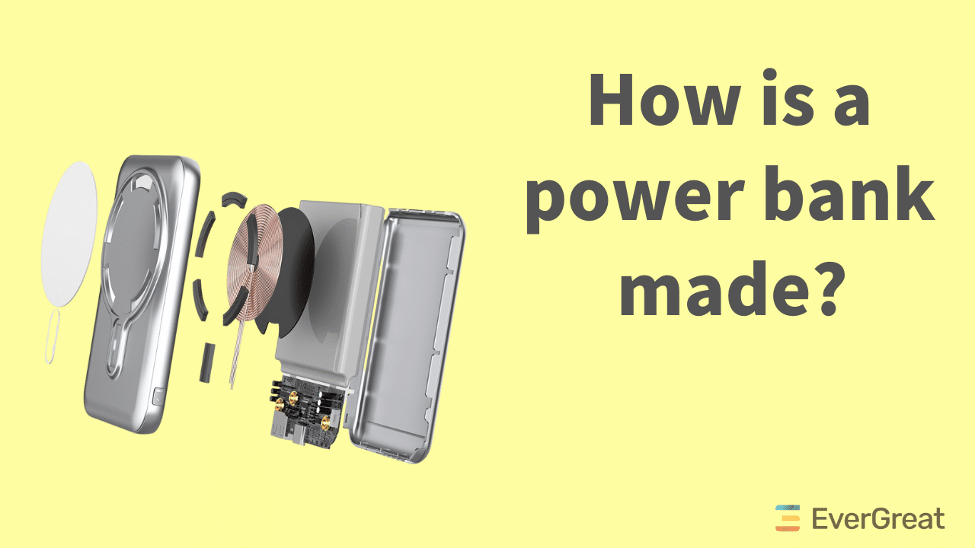

Manufacturing a power bank is more than just assembly. It requires a clear process, careful selection of fire-retardant casings, Grade-A battery cells, and a well-designed PCB with multiple safety protections. These core components determine the product’s final quality, safety, and lifespan.

You now know the basics of what goes into a power bank. At first glance, it may look simple—just a circuit board, battery cells, and a case. However, to turn an idea into a high-quality, market-ready product requires a detailed process. Let’s walk through the step-by-step journey we take with our clients.

Step 1: Defining Your Product Vision

Everything starts with your idea. We sit down with clients to define the product specifications. This includes the capacity (like 10,000mAh or 20,000mAh), desired size and weight, and special features like fast charging, wireless capabilities, or multiple ports. We also discuss the target market to ensure the product has the right certifications, such as CE, FCC, and RoHS, right from the start.

Step 2: Selecting Premium Components

This is where quality is built in. The cells are the core, and we only use brand-new, Grade-A lithium-ion or lithium-polymer cells. This guarantees performance and safety. For the casing, we choose V0 fire-retardant plastics or durable aluminum alloy for heat dissipation. Finally, the PCB is engineered with advanced protections like TVS (Transient Voltage Suppression) to ensure stable, safe charging.

Step 3: Prototyping and Rigorous Testing

Once the design and components are chosen, we create a prototype. This is not just a model; it’s a fully functional unit that we put through intense testing. We check its charging speed, actual capacity, and durability. Most importantly, we test all safety features, including protections against overheating and short-circuits, to ensure it meets international standards.

Step 4: Scaling to Mass Production and Branding

With an approved prototype, we move to mass production. Our quality control team monitors every stage, from sourcing components to final assembly. At the same time, we work on branding. We help customize the power bank with your logo, colors, and design tailored packaging that reflects your brand identity. This includes user manuals and any branded accessories. This detailed process might seem complex, which is why brand owners like you often have more specific questions. Let’s dive into some of the most common ones we hear every day.

Are all power banks made in China?

Worried about sourcing everything from one country? This dependency can feel risky. We’ll explore the global manufacturing landscape to give you clarity and confidence in your supply chain strategy.

While China is the dominant manufacturing hub for power banks due to its mature supply chain, it’s not the only option. Countries like Vietnam and India are emerging. However, China’s ecosystem for electronics remains unmatched in speed, cost, and component availability.

Many of our clients ask us this question. They see news about diversifying supply chains and wonder if they should look elsewhere. The reality is that the vast majority of the world’s power banks are manufactured in China, especially in cities like Shenzhen. This is not just by chance. Over decades, a massive and highly efficient ecosystem has been built here.

Why China Dominates Manufacturing

The primary reason is the supply chain. Almost every component needed for a power bank is made here. You can get battery cells, PCBs, casings, cables, and packaging all from suppliers located within a few hours of each other. This proximity dramatically speeds up development and production. I remember working with a client who wanted to try manufacturing in another country. After months of delays trying to import simple components, they returned to us because the speed and integration here are just unbeatable.

Comparing Manufacturing Regions

While China is the leader, other regions are growing. It’s helpful to see how they compare.

| Region | Pros | Cons |

|---|---|---|

| China | Mature supply chain, low cost, fast production, experienced labor. | Geopolitical risks, rising labor costs. |

| Vietnam | Lower labor costs, favorable trade agreements with some nations. | Less developed supply chain, reliance on imported parts. |

| India | Large domestic market, government incentives. | Infrastructure challenges, complex regulations. |

Ultimately, for most brands looking for efficiency, cost-effectiveness, and access to the latest technology, China remains the most practical choice for manufacturing power banks.

Which company produces the best power bank?

Searching for the "best" manufacturer is overwhelming. You risk choosing a partner that doesn’t fit your brand’s unique needs. Let’s define what "best" truly means for your business.

The "best" company isn’t one-size-fits-all. It depends on your needs. The best partner provides high-quality components, robust safety features, transparent communication, and reliable support for your business goals, whether you are a startup or an established brand.

I often tell new clients that searching for the single "best" company is the wrong approach. The "best" partner for a startup with a unique design is different from the "best" partner for a large retailer needing millions of standard units. Instead, you should look for a company that demonstrates excellence in the areas that create a high-quality product. A great power bank is not simply about assembling parts. It requires comprehensive control over materials, safety, and intelligent power management. A good partner will guide you through the manufacturing journey we just discussed, from initial vision to final product. They will be obsessed with the details at every step. For example, they will ensure the materials are top-notch, with fire-retardant casings and Grade-A battery cells. Their engineers will design a PCB with multiple layers of protection, not just the basics. The "best" company is the one that acts as a true partner, investing in your product’s quality as if it were their own.

Who to make a power bank with?

You have a great idea for a power bank but don’t own a factory. Finding the right partner is critical. Choosing the wrong one can delay your launch and hurt your brand.

You should partner with an experienced OEM/ODM manufacturer. They handle everything from design and sourcing to production and quality control. Look for a partner with a strong engineering team, a proven track record, and a deep understanding of your target market.

Finding the right partner is the most important decision you will make. You need more than just a factory; you need a team that can guide you. This is where understanding the difference between OEM and ODM comes in.

Understanding OEM vs. ODM

- OEM (Original Equipment Manufacturer)1: This is when you have your own design ready. You provide the full specifications, and the manufacturer builds it for you. This model is great for brands with strong in-house R&D teams. We work with many clients this way, ensuring their intellectual property is protected while bringing their vision to life.

- ODM (Original Design Manufacturer)2: This is when you select a product from the manufacturer’s existing catalog and customize it with your branding, colors, and packaging. It’s much faster and requires less investment, making it perfect for startups and retailers who want to get to market quickly. We also offer a hybrid model, combining ODM efficiency with OEM innovation.

What to Look for in a Partner

Whether you need OEM or ODM, a great partner provides more than just production. They should offer full-cycle support.

| Service | Why It Matters |

|---|---|

| Product Consultation | Helps you choose the right features for your market. |

| Cost Analysis | Provides transparent pricing so you can plan your budget. |

| Rapid Prototyping | Lets you see and test a sample before mass production. |

| Certifications | Ensures your product meets international standards (CE, FCC, RoHS). |

| After-Sales Support | Gives you and your customers peace of mind with a solid warranty. |

A true partner invests in your success. They should be responsive, professional, and act as an extension of your own team.

Who created the power bank?

Ever wondered where this essential gadget came from? The history is often overlooked. Understanding its origin gives insight into the product’s evolution and future trends in the industry.

A Chinese company called Pisen created the first practical "power bank" in 2001. Their initial design combined batteries with a control circuit, made for an Antarctic expedition team. This invention paved the way for the portable chargers we use every day.

The story of the power bank is quite interesting. Before 2001, people used battery packs, but they were often clumsy and inefficient. The first device that we would recognize as a modern power bank was created for a very specific need. A Chinese Antarctic expedition team needed a way to keep their cameras and equipment charged in the extreme cold, where batteries die quickly.

The Birth of an Industry

Pisen, a Chinese electronics company, developed a solution. They put AA batteries into a case with a control circuit, creating the first portable power source, or "power bank." It was a simple idea, but it solved a huge problem. From that practical beginning, an entire industry was born. The concept quickly caught on as mobile phones, especially smartphones, became more powerful and power-hungry. The need for on-the-go charging grew, and the power bank became an essential accessory for millions.

Evolution of Power Bank Technology

The technology has come a long way since that first simple device.

- Early 2000s: Simple battery packs with basic charging circuits.

- Late 2000s: Introduction of Lithium-ion and Lithium-polymer cells, making power banks smaller and lighter.

- 2010s: The rise of fast-charging technologies like Qualcomm Quick Charge (QC) and USB Power Delivery (PD).

- Today: Smart power banks with wireless charging, multiple ports, GaN technology, and intelligent power management for optimal efficiency and safety.

Understanding this history helps us appreciate the innovation that continues to drive the industry forward.

Conclusion

Manufacturing a quality power bank is a detailed process. Choosing the right partner who focuses on materials, safety, and comprehensive support is key to your brand’s long-term success.