Are you tempted by those super low-priced power banks? Many brands see quick sales, but a hidden cost often follows. I have seen this happen too many times.

Cheap power banks often cut corners on quality, leading to high failure rates and customer dissatisfaction. While they offer a low upfront cost, the long-term impact on brand reputation, warranty costs, and customer loyalty usually makes them a poor investment for any serious brand.

After seeing countless brands struggle with these issues, I know the allure of low prices. But before you dive into the budget market, let’s look at the real costs.

How do low-cost power banks impact brand reputation for private-label importers?

Worried about your brand’s image? Cheap power banks can quickly tarnish years of hard work. I have witnessed this firsthand with many clients.

Low-cost power banks often fail quickly or perform poorly, leading to negative reviews and customer complaints. This directly erodes trust, reduces repeat business, and can permanently damage a private-label importer’s brand reputation in the competitive market.

My experience tells me that a brand’s reputation is its most valuable asset. When a private-label importer sources cheap power banks, they are putting their name directly on a product that is often unreliable. I have seen how quickly a few negative reviews can spread online, especially on e-commerce platforms. Customers do not blame the factory; they blame the brand whose logo they see on the device. When power banks stop charging or break after only a few uses, customers feel cheated. According to a 2023 study on online reviews, 88% of consumers trust online reviews as much as personal recommendations. A flood of one-star reviews, complaints to customer service, and public shaming on social media can severely damage a brand’s image. People then avoid buying anything else from that brand. This creates a lasting impression that the brand sells low-quality goods, making it very hard to attract new buyers. It also makes existing customers leave. My team and I work hard to help brands avoid these pitfalls.

The Erosion of Trust

When a product fails, trust breaks. Customers expect a power bank to work when they need it most. If it does not, they feel let down. This feeling directly links to the brand. Repeated failures teach customers to distrust the brand. They will then choose competitors.

Long-Term Market Perception

A brand known for cheap, faulty products struggles. This perception is hard to change. Marketing efforts become less effective. Gaining market share gets harder. New product launches face skepticism. One case study showed a 30% decrease in sales for a brand after widespread reports of their low-quality electronics failing prematurely.

Reduced Customer Loyalty

Loyal customers are key to success. Cheap power banks destroy this loyalty. People will not buy again from a brand that let them down. They will tell friends and family about their bad experience. This hurts future sales and growth. Statistics show that increasing customer retention rates by just 5% can increase profits by 25% to 95%. A bad experience with a cheap power bank can easily negate these potential gains.

What safety and quality checks should importers require when sourcing budget power banks?

Thinking about sourcing budget power banks? Overlooking crucial checks is a big mistake. I learned this through years in the industry.

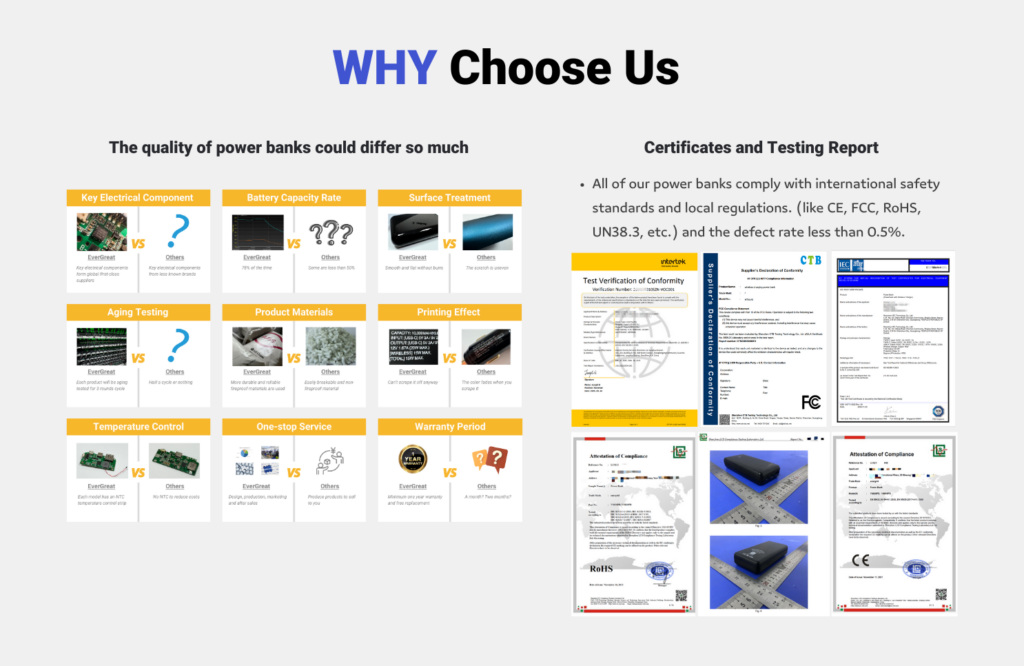

Importers must demand strict quality control, including battery cell testing, circuit protection validation, and robust casing checks. Essential safety certifications like CE, FCC, and RoHS are non-negotiable to protect consumers and uphold brand integrity.

When I advise clients on sourcing, I always stress the importance of quality assurance. It is not just about performance; it is about safety. A poorly made power bank can overheat, catch fire, or even explode. I have seen factories cut corners on critical components, like using inferior battery cells or skipping protection circuits. Importers must go beyond basic visual checks. They need to insist on rigorous testing at every stage. This means checking the battery cells before assembly, verifying the PCBA (printed circuit board assembly) for correct protection, and testing the finished product under various conditions. My team at EverGreat makes these checks standard. We ensure every unit meets the highest safety and quality benchmarks. This protects both the end-user and the brand’s reputation.

Key Quality Control Steps

Importers need a clear checklist for quality control. It starts with components.

- Battery Cell Inspection: Always specify A-grade cells. Demand test reports for capacity and cycle life. Watch out for recycled or B-grade cells. These fail fast. A-grade cells typically offer a cycle life of 500+ cycles with minimal capacity degradation, while B-grade or recycled cells may only last for 200 cycles or less and can exhibit significantly reduced capacity from the start.

- PCBA Protection Circuits: Verify that overcharge, over-discharge, short-circuit, and over-current protections are all present and working. This prevents damage to devices and users. Real-world incidents have shown that power banks lacking these circuits can overheat and even explode, causing property damage and personal injury.

- Casing Material Quality: The outer shell needs to be durable. It must withstand drops and impacts. It must also be flame-retardant. Inferior plastics crack easily.

- Connector Durability: USB ports and charging cables get used often. They must be strong. Test for insertion and extraction cycles. Loose ports cause charging issues.

Essential Safety Certifications

Certifications are not just paper; they are proof of safety.

- CE, FCC, RoHS: These are minimum standards for global markets. They show products meet basic safety, health, and environmental protection requirements. Note that compliance with RoHS (Restriction of Hazardous Substances) ensures the product does not contain harmful materials like lead or mercury.

- UL Certification (if applicable): For some markets, like the US, UL is critical. It shows rigorous product safety testing.

- MSDS for Batteries: A Material Safety Data Sheet is needed for shipping. It confirms battery safety for transport. It’s crucial to consult the latest regulations from the International Air Transport Association (IATA) regarding the shipment of lithium-ion batteries, as these are updated regularly.

Importers must require proof of these certifications. They should also perform spot checks. This ensures ongoing compliance.

Is the lower price worth the higher return rate and warranty costs for brands?

Is that low price tag really a deal? Many brands overlook the hidden costs. I’ve helped clients uncover these financial pitfalls.

No, a lower price for budget power banks is rarely worth the financial and operational burden of high return rates and warranty claims. These hidden costs often exceed initial savings, impacting profitability, straining resources, and damaging brand perception over time.

From my perspective, many brands fall into the trap of focusing only on the unit cost. They see a power bank for a dollar less and think they are saving money. But this is a short-sighted view. I have seen how quickly those "savings" evaporate when a brand starts receiving a wave of returns. Each returned unit costs money: shipping fees, processing fees, labor for customer service handling the complaint, and the cost of replacing the faulty product. My team helps clients analyze the total cost of ownership. We show them that a slightly higher upfront investment in quality drastically reduces these after-sales expenses. A product that performs well means fewer headaches, happier customers, and ultimately, a more profitable business. High return rates also signal quality issues to retailers and distributors, making them less likely to reorder. Some data suggests that electronics with a return rate exceeding 5% can see a decrease of up to 15% in reorder rates from major retailers.

The True Cost of Returns

Returns are not free. Each return adds to a brand’s expenses.

- Shipping and Handling: Brands often pay for return shipping. They also pay to ship a replacement. These costs add up fast.

- Replacement Unit Costs: Every faulty power bank needs replacing. This means buying more stock. It also means managing inventory for replacements.

- Labor and Customer Service: Handling returns takes time. Customer service agents spend hours on complaints. This is an operational cost.

- Reputational Damage: Negative experiences lead to bad reviews. This makes new sales harder. It affects future profits.

Warranty Claims and Beyond

Warranty claims extend beyond simple returns. They impact long-term costs.

- Warranty Fulfillment: Brands must honor warranties. This means replacing units for up to a year or more. Poor quality products trigger many claims.

- Loss of Customer Lifetime Value: A customer who gets a bad product might never buy from that brand again. This means losing all future potential sales from them. Studies show that the cost of acquiring a new customer can be five times higher than retaining an existing one.

- Supply Chain Strain: Managing high return volumes stresses the supply chain. It takes resources away from growth. It diverts focus from innovation.

I always tell my clients that investing in quality upfront is an investment in their brand’s future. It prevents these hidden costs from eating into their profits. Using a total cost of ownership (TCO) calculator can help quantify these hidden expenses, revealing the long-term savings associated with higher-quality products.

Conclusion

Cheap power banks offer short-term gains but create long-term problems. Prioritize quality for lasting brand success. I always advise my partners on this.