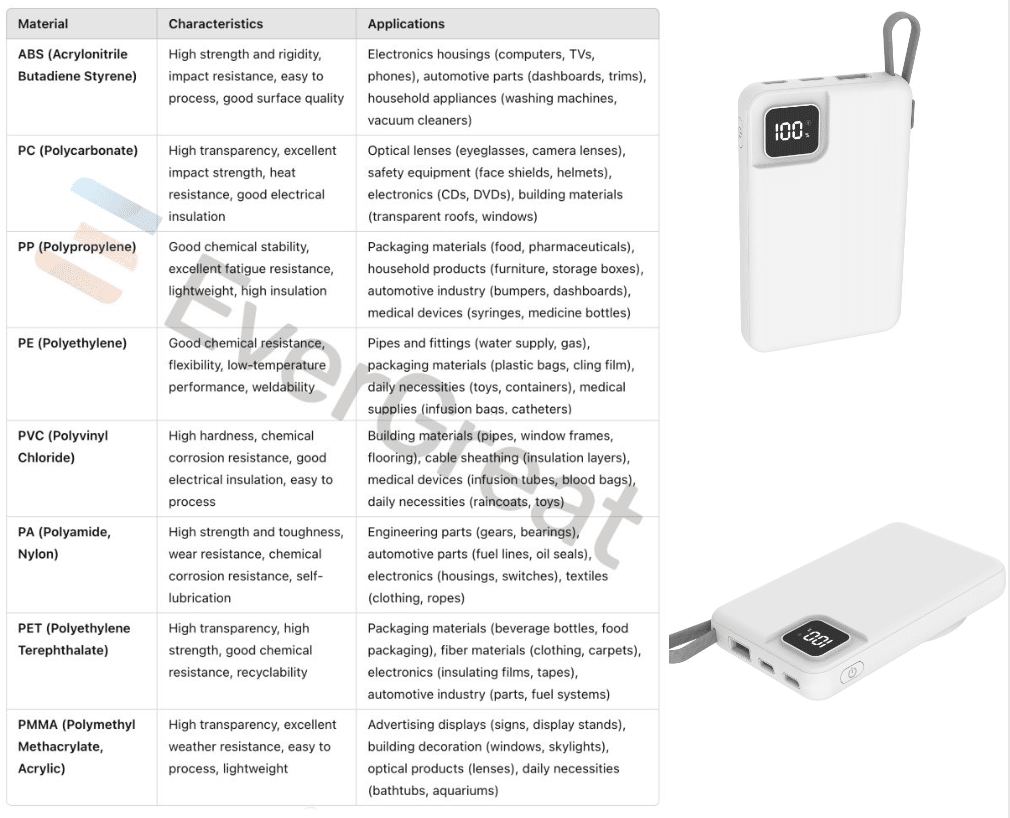

Following the materials of plastic cases mentioned in our previous post, I would like to continue to share several commonly used raw materials for plastic cases.

🪛 PVC (Polyvinyl Chloride) is a high-hardness plastic known for its chemical resistance and fireproof properties. It is widely used in pipes, cable coatings, and building materials such as window frames and flooring. Its waterproof and flame-retardant properties make it popular in the construction and electrical industries.

🪛 PC (Polycarbonate) is a transparent, tough, and impact-resistant plastic commonly used in CDs, eyeglass lenses, protective shields, and phone screens. It has excellent impact resistance and high-temperature tolerance, making it ideal for safety equipment and electronic products.

PET (Polyethylene Terephthalate) is a smooth, transparent plastic with good wear resistance, widely used in beverage bottles, food packaging, and fibers. It offers excellent gas and moisture barrier properties, high strength, and transparency, making it an ideal material for food packaging.

🪛 PA (Nylon) is a high-strength, wear-resistant engineering plastic often used in gears, bearings, and mechanical parts. With its excellent mechanical properties and chemical resistance, PA is particularly suited for high-stress and frictional components, widely applied in industrial and electronic fields.

🪛 PMMA (Polymethyl Methacrylate, Acrylic) is a highly transparent and weather-resistant plastic with a light transmittance of up to 92%. It is commonly used in lampshades, advertising signs, and transparent displays. Its excellent optical properties and weather resistance make it ideal for outdoor displays and optical equipment.

Each material has its own advantages. As long as it is used well, even ordinary materials can be used to make amazing products.

📈 Stay Connected:

Follow me for updates on portable chargers technology.