Frustrated with power banks that fail too soon? Many people face issues like rapid battery drain or devices simply not working. Understanding these common problems can help you choose better products.

From my experience, most power bank quality issues stem from poor initial inspections, using unqualified materials, or unstandardized production. Problems like damaged batteries, scratched housings, or circuit board shorts all point to a lack of strong process control and attention to detail during manufacturing. A 2021 investigation found approximately 40% of power banks checked were faulty, citing lower-than-advertised capacity and sub-par batteries. Inferior components in power banks can lead to circuit board failures.

It is not just bad luck when a power bank fails; it is usually a result of management choices and operational processes. Let’s dig deeper into the specific ways these issues show up, starting with a problem I have seen many times myself.

Why do some batteries swell after shipping?

Have you ever opened a package to find your new power bank has a bulging battery? It is a worrying sight that can make you wonder if your product is even safe to use.

Batteries swell after shipping mainly due to internal gas buildup from chemical reactions, often caused by overcharging, excessive discharge, heat exposure during transit, or manufacturing defects within the battery cells themselves, especially if they are low quality.

When I look at a swollen battery, I know something went wrong at a fundamental level. This swelling, known as "gassing," happens because the internal chemistry of the lithium-ion cell is reacting abnormally. This is often tied to either the quality of the cell itself or how it was handled. For example, if a battery cell is made with impurities or has a damaged separator, it can react more easily. During shipping, especially in containers that can get very hot, a slight manufacturing defect can become a big problem. Also, if a power bank is overcharged before it even leaves the factory, or if its protection circuit fails, it adds stress to the battery. We often advise clients to consider environmental testing during development to simulate harsh shipping conditions. It helps catch these issues before they become widespread. Swelling in lithium-ion batteries is due to internal gas generation from chemical reactions, often from overcharging, physical deformation, or extreme heat. Gases released can include carbon dioxide, carbon monoxide, and volatile organic compounds. The Solid Electrolyte Interface (SEI) layer growth leads to battery swelling as lithium ions reacting with the electrolyte can form ethylene gas. Manufacturing defects like uneven electrode coating, inaccurate electrolyte injection, and poor battery sealing can also cause swelling. Extreme temperatures or being in a discharged state for an extended period can cause swelling due to gasses being released inside the battery cells.

Common Causes of Battery Swelling

- Internal Defects: Poor quality materials or manufacturing flaws within the cell.

- Overcharging: Charging past the safe voltage limit, creating gas.

- Over-discharging: Draining the battery too low, damaging its structure.

- Heat Exposure: High temperatures during storage or transit speeding up reactions.

- Physical Damage: Dents or punctures that compromise cell integrity.

Impact of Swollen Batteries

| Problem | Risk | Prevention |

|---|---|---|

| Safety Hazard | Fire, explosion, toxic gas release | High-quality cells, proper charging circuits |

| Device Damage | Case cracking, internal component stress | Robust casing, strict quality checks |

| Performance Loss | Reduced capacity, faster degradation | Reliable battery management systems |

Overcharging can cause all lithium ions to move to the negative electrode, disrupting the balance and causing structural collapse. Over-discharging damages the protective SEI film, leading to swelling. Improper storage where voltage drops below 2V can trigger chemical reactions producing gas. Lithium is sensitive to heat; high internal temperatures cause gas buildup and swelling. External damage can worsen this. Between 2019 and 2024, 58 reported fires were linked to power banks, with a high of 13 incidents in 2024. Lithium-ion batteries can be highly flammable; incorrect handling can cause fires, explosions, or toxic gas release. A 2025 report cites incidents of plane cabins filling with smoke due to burning power banks. Overheating may cause permanent damage, leading to battery swelling, venting, and short-circuiting. Anker recalled over a million power banks due to overheating and fire risks, with 19 reports of fires and explosions, including burn injuries and property damage.

How to identify weak soldering or bad assembly?

Are you tired of power banks that suddenly stop working or have loose parts inside? These issues often point straight to problems during the assembly process.

Identifying weak soldering or bad assembly often involves physical inspection for uneven joints, excess solder, or misaligned components, and functional testing for intermittent connections or complete device failure. These are key signs of unstandardized production.

From my observation, weak soldering is like a hidden enemy; it does not always show up right away. You might have a power bank that works fine for a few weeks, then suddenly fails. This is because a cold solder joint – one that did not heat up enough to bond properly – can slowly break apart with vibration or minor impacts. We look for dull, lumpy joints rather than shiny, smooth ones. Bad assembly also shows up in different ways, like misaligned USB ports that make it hard to plug in cables, or cases that do not quite close, leaving gaps where dust or moisture can enter. I have personally seen how these small details can lead to major product returns. Our team always focuses on detailed visual inspections and even X-ray checks for critical solder points to ensure robustness. Weak soldering can result in intermittent connections or complete device failure. Skewed or damaged USB ports can result in overheating, creating a fire hazard.

Signs of Poor Soldering

- Dull or Grainy Joints: Lacks the smooth, shiny appearance of good solder.

- Too Much Solder (Bridging): Solder connecting two points that should be separate, causing short circuits.

- Not Enough Solder: Weak connection, prone to breaking.

- Cracked Joints: Visible cracks, often due to poor adhesion or stress.

- Cold Joints: Solder did not melt and flow correctly, looks lumpy.

Assembly Issues to Watch For

| Issue | Description | Consequence |

|---|---|---|

| Misaligned Components | USB ports not lining up, buttons sticking | Difficulty using, user frustration |

| Loose Connections | Wires not properly secured, leading to intermittent power | Unreliable charging, total failure |

| Gaps in Casing | Housing not fully sealed, allowing dust/water entry | Short circuits, component damage, reduced lifespan |

| Incorrect Parts | Wrong screws or components used | Structural weakness, functional defects |

Dull solder joints may have a milky finish or be covered with flux. Insufficient wetting of the solder pad can occur if the board is dirty or heat isn’t applied to the pad. Misaligned USB ports or sticking buttons can cause user frustration.

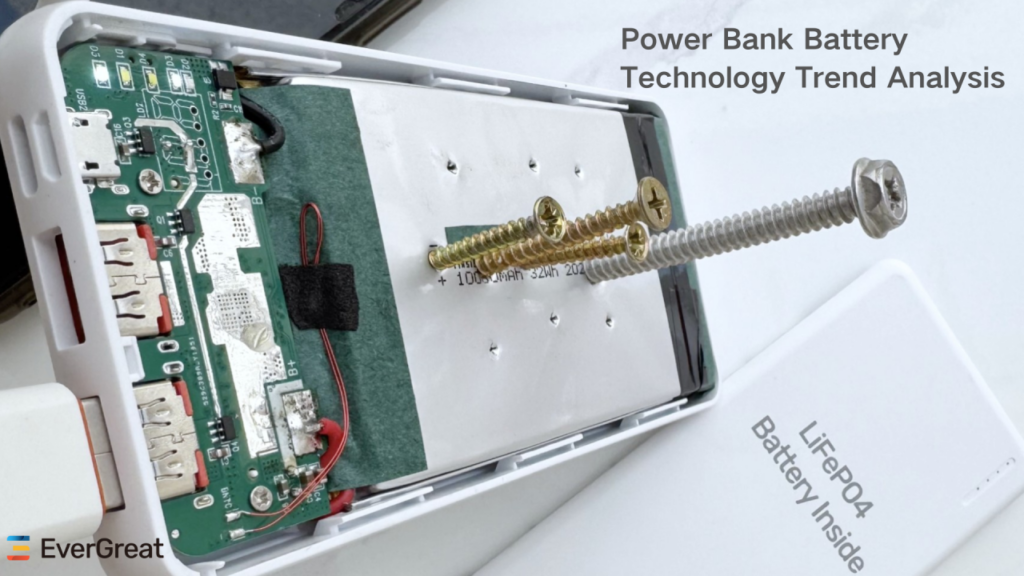

How can pre-shipment inspection prevent major losses?

Worried about receiving a huge order of faulty products from your supplier? The financial hit from returned goods or a damaged brand reputation can be immense.

Pre-shipment inspection (PSI) acts as a critical final safeguard, catching defects like damaged batteries, scratched housings, or short circuits before products leave the factory. This proactive step prevents major financial losses, protects brand reputation, and ensures product quality matches agreed-upon standards.

I always tell our clients that a good pre-shipment inspection is not just an expense; it is an investment that pays for itself many times over. Imagine a scenario where a whole batch of 10,000 power banks has a subtle charging defect that only appears after a few cycles. Without PSI, these units ship, reach customers, and then start failing. The cost of returns, shipping, and losing customer trust can sink a business. Through PSI, my team and I perform comprehensive checks, from confirming correct packaging and labeling to testing the actual function of a sample of units. We make sure the power banks meet all specified criteria, including basic safety, performance, and appearance. This is where we catch those damaged batteries, scratched housings, or even confirm that the PCBA has no short circuits. Pre-shipment inspections streamline quality control, reducing the need for extensive post-shipment checks. PSI ensures products meet quality standards and compliance requirements before they reach customers and helps to verify product quality, quantity, and compliance.

Key Aspects of Pre-Shipment Inspection

- Quantity Verification: Confirming the correct number of units.

- Visual Inspection: Checking for cosmetic defects like scratches, dents, or incorrect branding.

- Workmanship Check: Examining assembly quality, such as casing fit and button responsiveness.

- Functionality Testing: Powering on, charging input/output tests, capacity verification.

- Safety & Compliance: Checking certifications, labeling, and basic safety features.

- Packaging Inspection: Ensuring proper packing materials, labeling, and shipping marks.

Benefits of Robust Pre-Shipment Inspection

| Benefit | Description | Impact |

|---|---|---|

| Risk Mitigation | Catches defects early, preventing mass distribution of faulty products. | Reduces financial losses from returns and replacements. |

| Quality Assurance | Confirms products meet specified quality standards before shipping. | Protects brand reputation and builds customer trust. |

| Cost Savings | Avoids costly recalls, reverse logistics, and customer service burdens. | Improves profit margins and operational efficiency. |

| Supply Chain Control | Provides leverage for negotiating with suppliers on quality issues. | Strengthens supplier relationships and accountability. |

| Brand Protection | Ensures customers receive reliable, safe products, upholding brand image. | Fosters customer loyalty and positive reviews. |

A case study showed how PSI saved an electronics manufacturer from a potentially disastrous situation. Key areas of quality control inspection include visual inspection of components, performance of charging capabilities, measurement of electronic function, and on-site testing of safety protections. Functionality tests confirm that the product operates as intended, while safety testing checks for hazards like electrical faults. PSI reduces costs associated with returns, legal issues, and quality control while enhancing customer loyalty and brand reputation. By identifying defects before shipment, companies avoided high costs associated with returns, repairs, and recalls. Pre-shipment inspections help ensure products meet regulatory requirements, preventing legal repercussions and potential financial penalties.

Conclusion

Understanding the core reasons for power bank quality issues, from swollen batteries to weak soldering and lack of pre-shipment checks, is vital. Quality is a result of good management and strict process control, not luck.