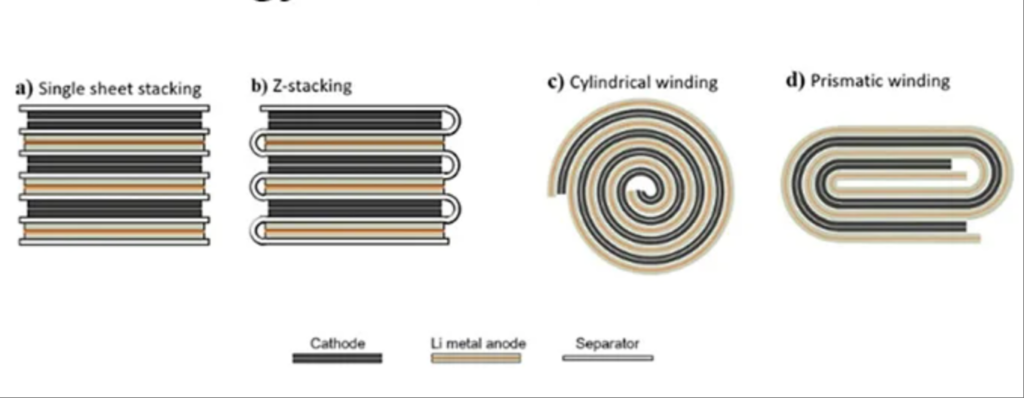

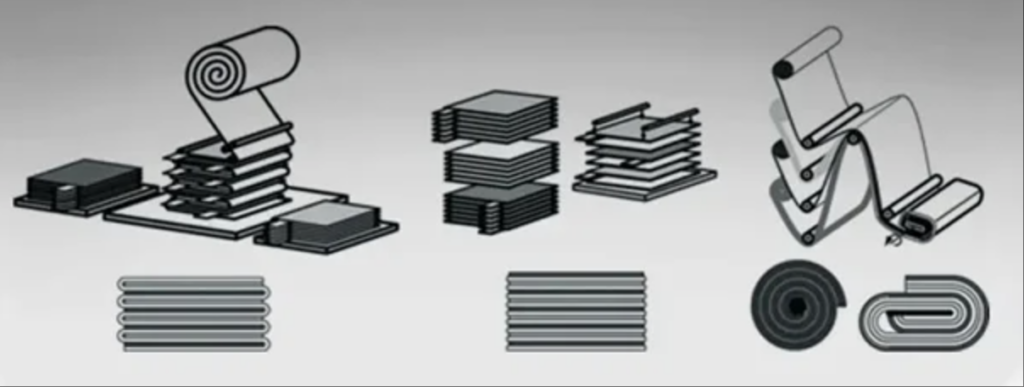

In semi-solid-state battery design, the assembly method of electrodes directly affects the energy density, thermal behavior, and overall reliability of the cell. Generally, there are two main processes: the traditional winding (jelly-roll) method and the stacking method.\

The stacking process involves layering the coated positive and negative electrode sheets with separators one by one before sealing. Each approach has its own pros and cons, but for semi-solid electrode systems (solid/gel or semi-fluid electrolyte structures), the stacking process offers unique adaptability and performance advantages.\

This article explains the principles, advantages, and value of stacking technology—especially for power bank applications.

1. What Is the Stacking Process? (Brief Overview)

Typical workflow (for pouch or prismatic stacked cells):

-

Electrode coating and drying

-

Slitting/cutting

-

Trimming and flattening electrode sheets

-

Stacking (alternately placing positive–separator–negative layers)

-

Tab welding (either during or after stacking)

-

Packaging (pouch or metal case)

-

Electrolyte injection (for semi-solid systems, this involves a specific filling or soaking method)

-

Vacuum drying

-

Formation and aging test

Because stacking requires high precision in electrode size, alignment, and uniformity, it demands advanced process control and a high degree of automation.

2. Key Advantages of Stacking Technology

(1) Higher Volume Utilization and Energy Density

Principle:\

Stacking maximizes the utilization of the electrode area, minimizing internal voids or wasted “rolled” layers found in wound cells.\

Result:\

For the same cell volume, stacked cells can contain more active material and better distribute electrode thickness, thus achieving higher volumetric energy density.\

Implementation Notes:

-

Optimize electrode width and stacking layer count for the best balance between capacity and thickness.

-

Semi-solid electrodes have special coating and compression characteristics, making stacking ideal for managing layer thickness and energy utilization.

(2) Lower Internal Resistance and Better High-Rate Performance

Principle:\

Stacked electrodes reduce the detour of current paths compared to wound structures, while improving uniform contact between layers and balancing current distribution.\

Result:\

Lower resistance means less heat generation and better support for high charging/discharging currents—ideal for fast-charging applications.\

Implementation Notes:

-

Maintain uniform electrode density and coating quality.

-

Optimize tab welding and current path design to prevent local voltage drops or hotspots.

(3) More Uniform Thermal Distribution (Better Heat Management)

Principle:\

Stacked cells have a flat geometry that allows heat to spread evenly across the surface. This design also facilitates the integration of thermal management materials like heat spreaders or thermally conductive gels near hot zones.\

Result:\

Fewer “hot spots,” more uniform temperature rise under high power, reduced thermal stress, and lower thermal runaway risks.\

Implementation Notes:

-

Combine with pouch or metal casing designs that include efficient heat paths.

-

Embed temperature sensors to support accurate BMS temperature monitoring and control.

(4) Higher Consistency and Process Control (Better Yield Rate)

Principle:\

Stacking is highly automatable, and each electrode sheet can be inspected individually (width, weight, coating quality), reducing defects caused by misalignment in winding.\

Result:\

Better consistency between cells in terms of resistance and capacity—crucial for pack-level balancing and quality control.\

Implementation Notes:

-

Enforce strict inspection standards for electrode dimensions and coating uniformity.

-

Use high-precision alignment and visual inspection systems in stacking equipment.

(5) Better Mechanical Strength and Swelling Resistance

Principle:\

During charge/discharge cycles, the volume change in stacked electrodes is more evenly distributed, unlike wound cells that create concentrated internal stress points.\

Result:\

Stacked cells are less prone to delamination or electrode deformation, offering superior structural stability after long-term cycling.\

Implementation Notes:

-

For semi-solid materials, ensure binder and interface compatibility for strong interlayer adhesion.

-

Design buffer structures (e.g., EVA pads or frame supports) to mitigate expansion stress.

(6) Better Adaptability for Complex Electrode Materials and High Loading Designs

Principle:\

Semi-solid electrodes typically feature higher active material loading and require precise control of thickness and electrolyte penetration. Stacking allows layer-by-layer tuning of these parameters.\

Result:\

Maintains ion conductivity and interfacial contact while increasing active material loading—achieving higher energy density without sacrificing cycle life.\

Implementation Notes:

-

Control coating and drying parameters carefully (wet film thickness, oven curve).

-

Manage electrolyte rheology during semi-solid filling (e.g., vacuum injection, heating, or vibration-assisted infiltration).

3. Challenges and Key Implementation Considerations

Stacking is not a “magic bullet.” Successful adoption requires overcoming several challenges:

-

High equipment and initial setup costs: Precision stackers, laser/ultrasonic welders, and auto-alignment systems are expensive, though they improve yield and reduce long-term costs.

-

Tight electrode manufacturing tolerances: Coating, drying, cutting, and trimming quality directly impact cell performance.

-

Semi-solid electrolyte injection difficulties: The rheological properties of semi-solid systems require customized filling methods (vacuum, heating, or vibration).

-

Packaging and sealing demands: Although safer than liquid cells, semi-solid systems still require excellent sealing and moisture protection.

-

Advanced inspection is essential: X-ray, optical cross-section analysis, in-line resistance/thickness measurement, and aging tests are necessary for consistent quality control.

4. Practical Value for Power Bank Applications

When applied to power banks, stacked semi-solid cells offer several tangible benefits:

-

Lighter and smaller size: Higher energy density allows more compact designs for portability and aesthetic differentiation.

-

Supports higher power output: Lower internal resistance and improved heat dissipation enable stable 30W–45W or higher outputs.

-

Longer cycle life and stability: Manufacturers can confidently offer longer warranties and lower failure rates.

-

Improved safety: Lower thermal runaway risk under stress or damage, helping meet stricter certification requirements.

Conclusion

The stacking process in semi-solid-state batteries is not a flashy marketing term—it’s a practical path to achieving higher energy density, better heat management, and production consistency.\

For manufacturers pursuing high-performance, thin, and reliable power banks, stacked semi-solid cells provide a significant competitive edge.

However, stacking requires strong manufacturing capability and precise process control.\

Partnering with suppliers that have mature stacking production lines, robust QC systems, and solid electrochemical testing capabilities is the key to turning this technical advantage into real market value.