In 2025, the global reliance on mobile devices, from smartphones and laptops to specialized industrial tools, has made portable power an indispensable utility. This booming demand has created a fertile ground for new players in the power bank market. The good news? You no longer need to own a multi-million dollar manufacturing plant to establish a successful and reputable power bank brand. Agile, smart, and strategic entrants, even small to medium-sized enterprises (SMEs), can carve out significant market share by focusing on smart partnerships, meticulous quality control, and targeted branding.

This guide will break down the essential steps and considerations for building your power bank brand, proving that you don’t need to be big to start – you just need to be smart and focused.

1. Identifying Your Niche: Where to Focus Your Power

The general power bank market is crowded. Your success as an agile entrant hinges on identifying and dominating a specific niche. Instead of a generic "power bank for everyone," consider who your ideal customer is and what their unique power needs are.

- High-End / Luxury Segment: Focus on premium design, exquisite materials (e.g., aerospace-grade aluminum, genuine leather, unique finishes), and advanced features like wireless charging, multi-device charging, or ultra-fast Power Delivery (PD) protocols. Target discerning professionals, tech enthusiasts, or corporate gifting channels where aesthetics and performance are paramount.

- Rugged / Industrial Use: Design power banks that are built to withstand harsh environments. Look for features like IP67/68 water and dust resistance, shockproof casings, built-in flashlights, and extreme temperature tolerance. Target construction companies, outdoor adventure brands, field service teams, or emergency responders.

- Eco-Friendly / Sustainable: Appeal to environmentally conscious consumers or businesses by using recycled plastics, bamboo, or other sustainable materials for casings. Explore integrating small solar panels for emergency charging or focus on exceptionally long-lasting battery cycles to reduce waste.

- Hyper-Specialized Applications: Could your power bank be optimized for a specific device, like drones, professional cameras, or medical diagnostic tools? This requires deep understanding of the device’s power requirements (voltage, current, connectors) and perhaps custom battery management systems.

- Corporate Gifting & Promotional: Offer highly customizable power banks with prominent branding opportunities. Focus on sleek designs, reliable performance, and competitive pricing for bulk orders. This B2B segment values consistent quality, quick turnaround times, and strong customer service.

- Gaming / High-Performance: Target gamers with power banks that offer ultra-fast charging (e.g., 65W+ PD for gaming laptops), multiple high-output ports, and perhaps RGB lighting or unique "gamer" aesthetics.

Actionable Tip: Conduct thorough market research. Analyze Amazon reviews, Reddit forums, industry reports, and competitor offerings. What are the pain points? What features are missing? Where is there an unmet need?

2. The Core of Your Product: Sourcing & Partnerships

Since you won’t be building a factory, your success is intrinsically linked to selecting the right Original Equipment Manufacturer (OEM) or Original Design Manufacturer (ODM) partner.

OEM vs. ODM:

- OEM (Original Equipment Manufacturer): You provide the design and specifications, and they manufacture it. This offers more control over the final product.

- ODM (Original Design Manufacturer): They have existing designs and you choose one to brand as your own. This is faster and often more cost-effective for initial entry.

- Many factories offer both, allowing for a hybrid approach (e.g., using their PCBA, but custom casing).

Choosing the Right Partner:

- Experience & Specialization: Prioritize factories with a proven track record specifically in power bank manufacturing, not just general electronics. Ask for their client list (if public) or references.

- Certifications: Verify their factory certifications (e.g., ISO 9001 for quality management, ISO 14001 for environmental management).

- Transparency: A reputable manufacturer should be transparent about their component sourcing and quality control processes.

- Communication & Project Management: Effective communication is crucial. Assess their responsiveness, English proficiency, and ability to manage projects efficiently.

- Minimum Order Quantity (MOQ): Ensure their MOQs align with your initial budget and risk tolerance. Start smaller if possible to test the market.

Component Quality is Paramount:

This is non-negotiable for safety, performance, and brand reputation.

1. Battery Cells: The heart of the power bank.

- Types: Lithium-Ion (Li-ion) 18650 cells are common, but Lithium-Polymer (Li-Po) pouch cells are gaining popularity for their flexibility in shape and often higher energy density for their volume.

- Brands Matter: Insist on cells from reputable manufacturers like LG, Samsung, Panasonic, Murata (formerly Sony), or ATL (Amperex Technology Limited). Avoid generic "no-name" cells, which are often cheaper but carry significant risks of lower capacity, rapid degradation, and safety hazards (overheating, swelling, fire).

- Cycle Life: Quality cells offer 500+ charge/discharge cycles before significant capacity degradation.

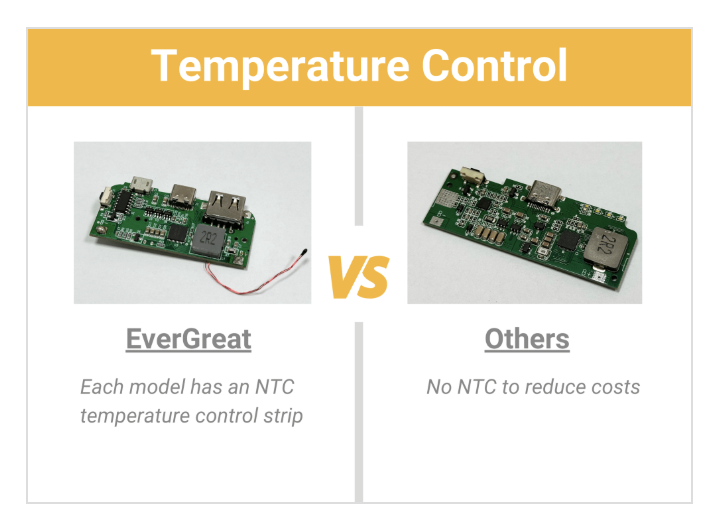

2. PCBA (Printed Circuit Board Assembly): The "brain" of the power bank.

- This circuit manages charging (input and output), power conversion, and crucial safety features.

- Key Protection Circuits: Ensure the PCBA includes protection against:

- Overcharge: Prevents batteries from being charged beyond their safe voltage.

- Over-discharge: Prevents batteries from draining too low, which can damage them.

- Short-circuit: Protects against electrical shorts.

- Over-current: Prevents excessive current flow during charging/discharging.

- Over-voltage/Under-voltage: Protects connected devices.

- Temperature Control: Monitors battery temperature to prevent overheating.

- Efficiency: A good PCBA will have high conversion efficiency, meaning less energy is lost as heat, leading to faster charging and more usable power.

3. Casing/Enclosure: Beyond aesthetics, the casing protects the internal components and helps dissipate heat. Materials can range from ABS plastic to aluminum alloy, influencing durability, weight, and premium feel.

Actionable Tip: Always request samples for thorough testing before committing to a bulk order. If feasible, arrange for an independent third-party inspection of the factory and the first production run.

3. Quality, Safety & Compliance: Building Trust

Your brand’s credibility and long-term success depend heavily on product safety and adherence to international standards. Failing here can lead to product recalls, legal issues, and irreversible damage to your reputation.

Key Certifications (Mandatory & Recommended):

- CE (Conformité Européenne): Mandatory for products sold within the European Economic Area (EEA), indicating compliance with EU safety, health, and environmental protection directives.

- FCC (Federal Communications Commission): Required for electronic devices sold in the United States, ensuring electromagnetic interference is within acceptable limits.

- RoHS (Restriction of Hazardous Substances): Originating in the EU, restricts the use of specific hazardous materials in electrical and electronic products. Increasingly adopted globally.

- UN 38.3: Crucial for all lithium batteries and devices containing them. This certification verifies that the battery cells and packs can withstand conditions during transport (e.g., pressure, temperature, impact, short circuit). Without it, shipping can be highly problematic.

- MSDS (Material Safety Data Sheet): Provides critical information about hazardous materials, essential for shipping and handling lithium batteries.

- UL (Underwriters Laboratories): Highly respected safety certification, particularly in North America. While expensive and not always mandatory, a UL certification for the battery cell or even the finished product significantly boosts buyer confidence.

- PSE (Japan), BIS (India), KC (South Korea): Specific regional certifications if you plan to enter these markets.

Internal Quality Control (QC):

- Beyond factory certifications, ensure your partner has a robust internal QC process:

- Incoming Material Inspection: All raw materials (cells, PCBs, casings) should be inspected upon arrival.

- In-line Production Checks: Quality checks at various stages of assembly to catch defects early.

- Final Product Testing: Every finished power bank should undergo a series of tests: actual capacity verification, charging/discharging efficiency, voltage stability, temperature monitoring during operation, and stress tests.

- Batch Testing: Random samples from each production batch should undergo more rigorous, destructive testing.

Warranty & Support:

Offer a clear and reasonable warranty period (e.g., 12-24 months) and provide responsive customer support. This demonstrates confidence in your product and builds long-term customer loyalty, especially in B2B relationships.

Actionable Tip: Always request copies of all relevant certifications from your manufacturer. Verify their authenticity if possible.

4. Branding, IP & Distribution: Your Market Footprint

With quality product secured, it’s time to build your brand identity and get your power banks into the hands of your target B2B buyers.

Branding & Value Proposition:

- Unique Selling Proposition (USP): What makes your brand different? Is it design, durability, specific features, sustainability, or unparalleled customer service?

- Brand Identity: Develop a compelling brand name, logo, color palette, and packaging design that resonates with your niche. Your packaging is your first physical touchpoint – make it count.

- Messaging: Craft clear, concise messaging that communicates your value proposition and speaks directly to your target B2B audience’s needs (e.g., "Empowering your mobile workforce," "Reliable power for critical operations").

Intellectual Property (IP) Protection:

- Trademark: Register your brand name and logo in your key markets to prevent others from using them.

- Design Patents: If your product has a unique aesthetic design, consider filing for a design patent.

- Confidentiality Agreements (NDAs): Always have a signed NDA with your OEM/ODM partner before sharing any sensitive design or business information.

Distribution Channels (B2B Focus):

- Direct Sales: Establish a professional e-commerce website (with B2B features like bulk pricing, invoicing) and potentially a dedicated sales team for larger accounts.

- Corporate Gifting Agencies: Partner with agencies specializing in corporate gifts and promotional products. They have established client bases looking for branded merchandise.

- Resellers & Distributors: Target tech distributors, office supply wholesalers, industrial equipment suppliers, or promotional product distributors. They can extend your reach to businesses of all sizes.

- Vertical Market Specialists: If you’ve chosen a niche (e.g., rugged power banks), partner with distributors who serve those specific industries (e.g., industrial suppliers, construction equipment dealers).

- Online B2B Marketplaces: Explore platforms like Amazon Business, Alibaba B2B, or specialized industry marketplaces.

- Direct Engagement: Attend industry trade shows, B2B expos, and networking events to meet potential clients and partners face-to-face.

Marketing & Sales Strategies:

- Content Marketing: Create valuable content (e.g., "Guide to Choosing Power Banks for Your Remote Team," "How to Extend the Life of Your Devices in the Field") that positions you as an expert and attracts B2B leads.

- LinkedIn Marketing: Leverage LinkedIn for professional networking, sharing industry insights, and direct outreach to decision-makers.

- SEO & SEM: Optimize your website for relevant B2B keywords. Consider targeted paid advertising campaigns.

- Case Studies: Once you have initial clients, develop case studies showcasing how your power banks solved their specific challenges.

Conclusion:

The journey of building a power bank brand from an agile, lean starting point is challenging but immensely rewarding. By intelligently identifying your niche, meticulously vetting your manufacturing partners, prioritizing uncompromising quality and safety, and strategically building your brand’s presence, you can confidently enter and thrive in this dynamic market. The opportunities are vast for those ready to power the future, one reliable charge at a time.